Reasons to Choose ADAP

The reasons to choose ADAP, connecting and visualizing the whole supply chain activities

Synchronize All Supply Chain Activities

Real-time, highly transparent web-based system

The Interface with the Ultimate Ease-of-use

High traceability enabled by production result management by lot

Synchronize All Supply Chain Activities;

Purchase, Task Planning, Logistics, and Customer

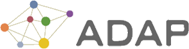

Centralized management of all operations that involves supply chain BOM

ADAP defines all activities in SCM, from purchase, work scheduling, logistics, customer orders, and others, by defining in and relating to supply chain BOM. You can understand all process and the current status of the product at a glance in ADAP.

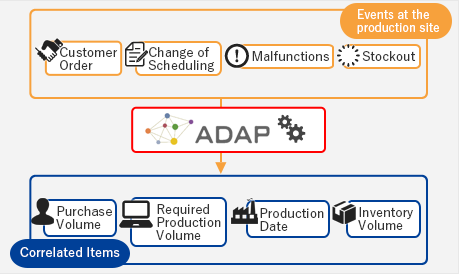

Flexible and Open Production Management

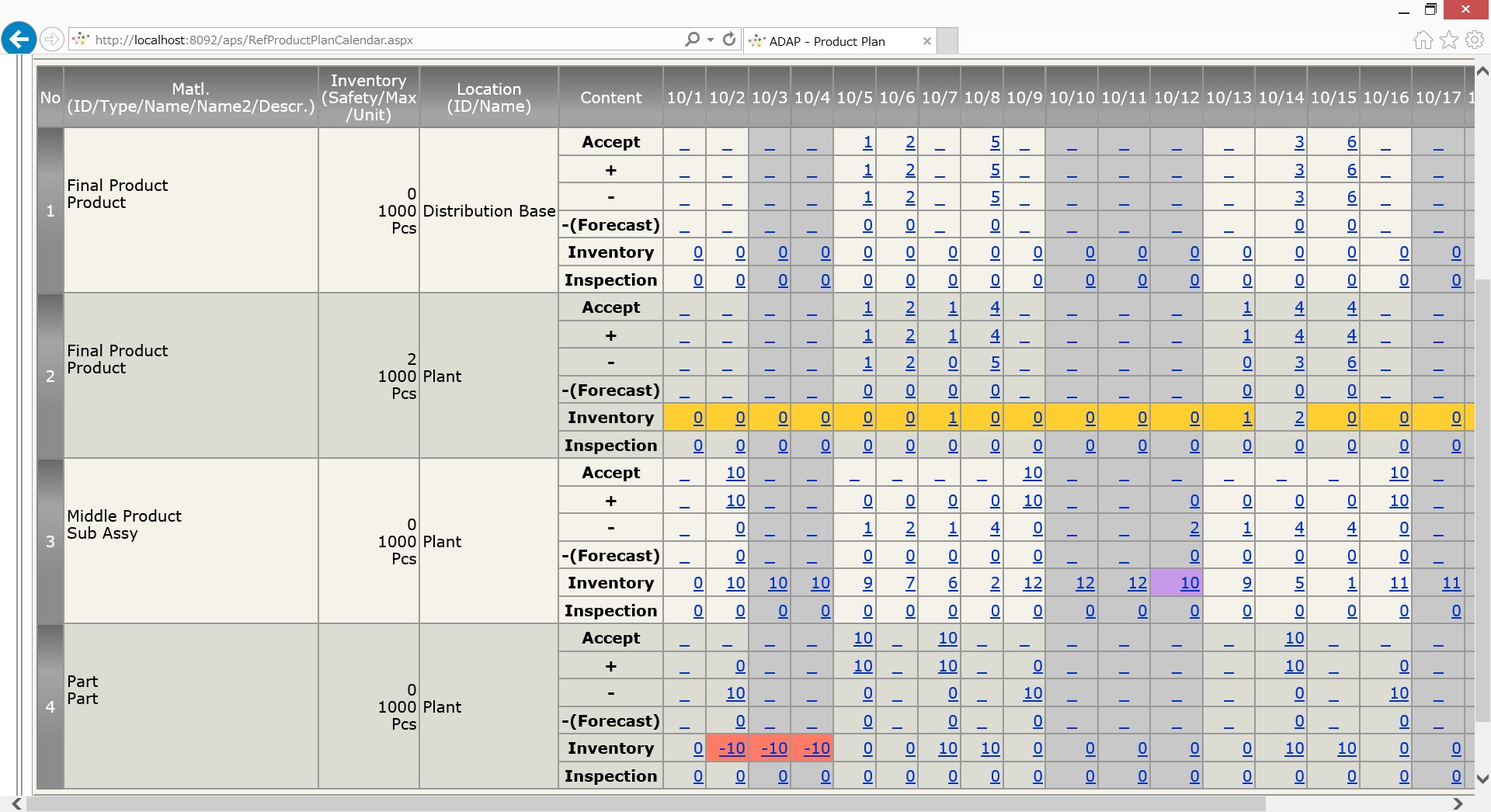

The instant you input the actual achievements in ADAP, it indicates the shorts and overs of stock/inventory based on the latest status. Whenever any activity is occurred, such as change of customer orders, change of scheduling or updates of work result in other production process, all information is linked together, re-analyzed and calculated automatically by ADAP.

Even if you encountered a gap between a plan and a result, you will immediately understand the overs and shorts based on the latest data, without going through the process of re-scheduling. Not only does ADAP indicate the number of shortage, it shows how many more days the current stock can suffice. You or any member of your company can intuitively understand and judge the necessity and timeframe for recovery.

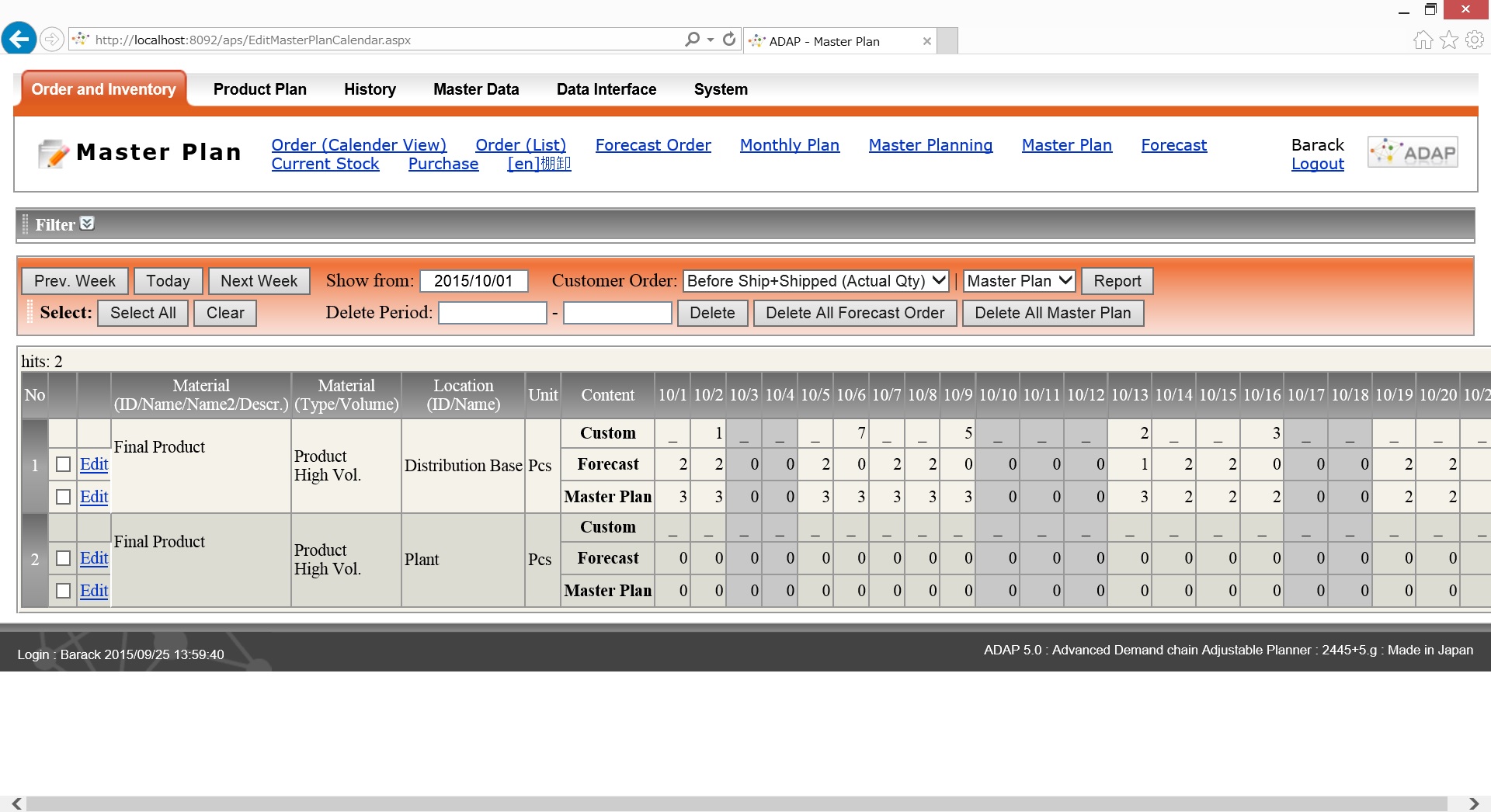

Confirmed Orders and forecasted Orders Stored All Together

You can specify confirmed customer orders and forecasted ones individually. Production scheduling can be planned flexibly, either based on confirmed customer orders only, or on the sum of both confirmed and forecasted customer orders.

The production scheduling is flexibly created in accordance with the needs at the production site.

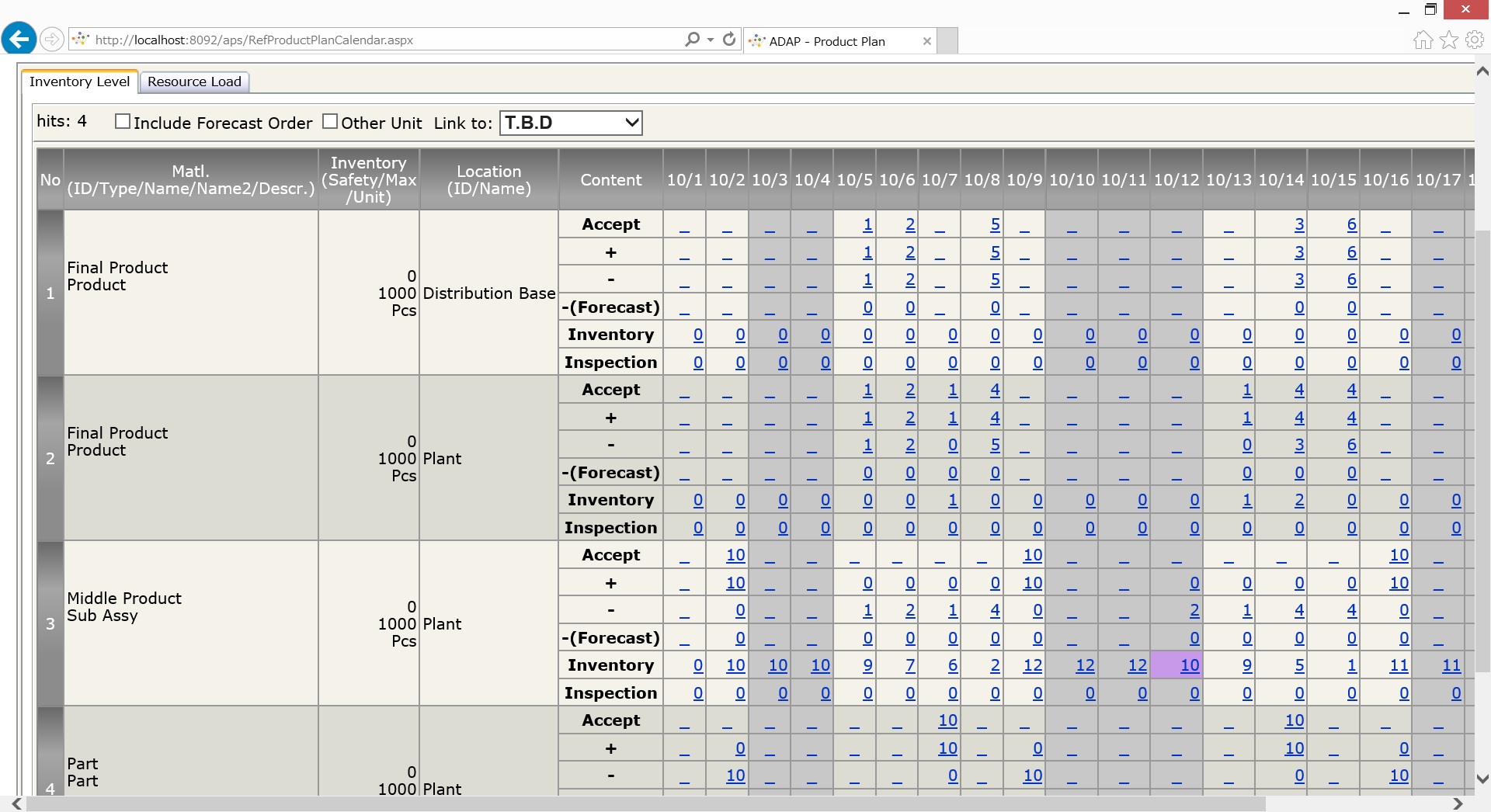

Resource Loads and Stock Transition at a Glance

Where are resource loads excessive? Where does it have a margin of resources? ADAP provides you with a management dashboard indicating the entire supply chain relationships.Managing Inventories with Logistics and Locations

Raw material inventories and intermediate stocks can be managed with a locational attribute so that you can recognize where they are located right now. When planning a production scheduling, you can specify which inventory located in which depot to use for the production. ADAP will trace and manage the locational data even inventories and stocks are transferred from one location to another.

Outsourcing work management

Not only purchasing and production scheduling, but outsourcing scheduling is also manageable in ADAP. It can handle outsourcing purchase by inventory supply, as well as shipping and receipt management of inventories.

Prioritized work management

By specifying priorities among plural workflows and various suppliers, ADAP supports your production for build orders and prodcuction.

Real-time, highly transparent web-based system

This Web-based system does not require any installation of special software or viewer on client machines. It can be linked to your existing ERP and/or MES. ADAP can be customized flexibly in accordance with the system in your company.

Flexible and Adjustable Planning ~ Allows you manual modifications and plans on daily basis~

Scheduling is planned on a daily basis in ADAP. Compared to the typical scheduling systems, ADAP provides you a simpler and easier structure of scheduling, which encourages you to use the production management system more frequently and permanently.

The Interface with the Ultimate Ease-of-use

High-speed processing without any waiting time (Powered by the High-speed APS Engine)

A high-speed processing is achieved by a memory processing and the APS Engine originally developed by Kozo Keikaku Engineering Inc. Equipped with the high-speed processor and flexible adjustment capability, ADAP enables you to repeatedly run and evaluate the planning cycle of "scheduling ->simulating->evaluation/adjustment" without waiting time for the computing time.

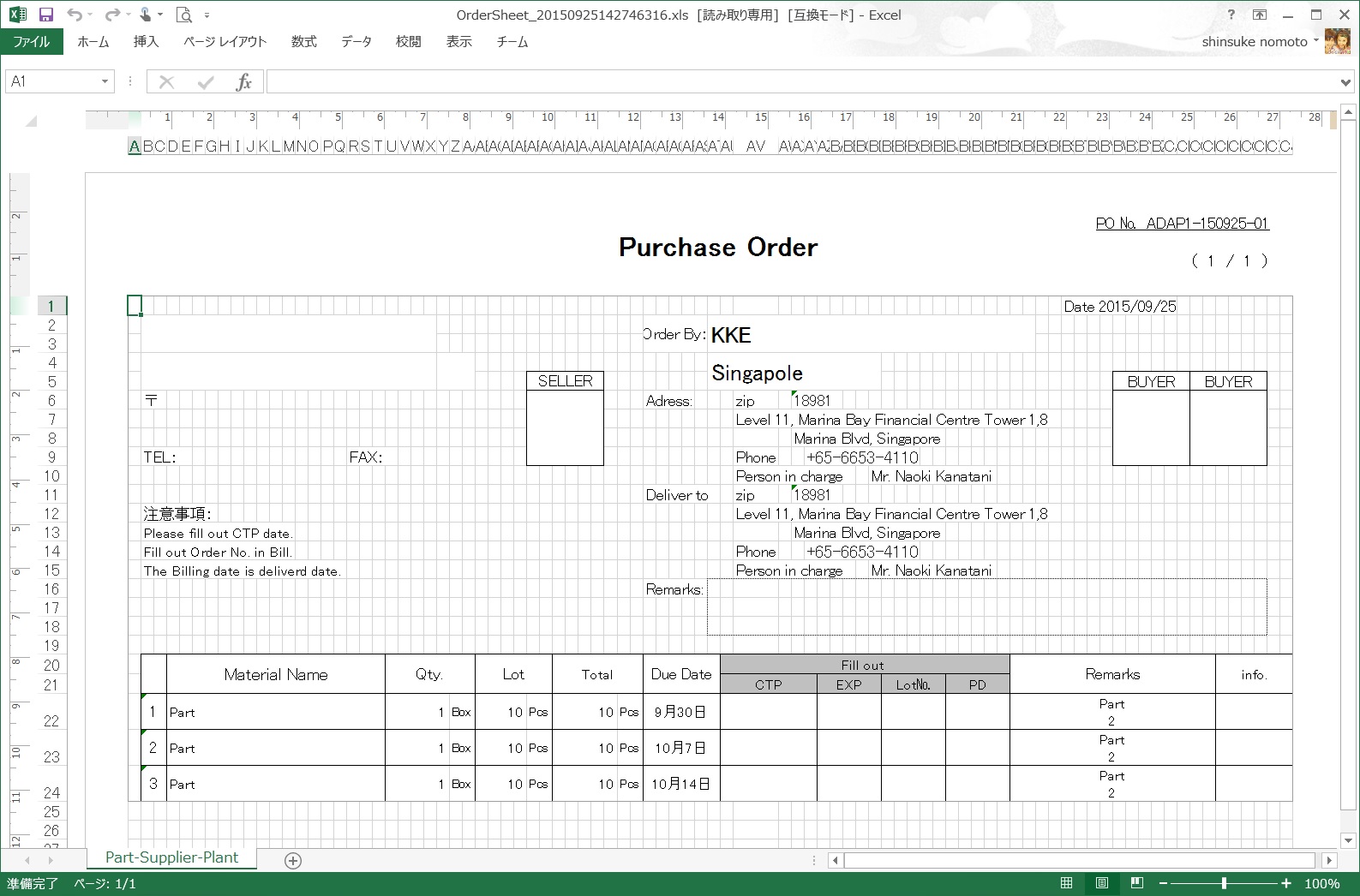

Customizable Output Report

Not only the output reports such as typical business forms, but also any original reports can be customized in compliance with your company requirements. Output Any form output The output forms can be prepared for each offices/factories individually, and the original report at a site can be created by spreadsheet.

Alert Indication by Distinct Colors

"Is that inventory sufficient?"

ADAP indicates the inventory volume at the planning in colors, i.e. yellow:short of targeted number, red:out of inventory/stock. The instinctive representation of the inventory/stock status helps you avoid out-of-inventory/stock.

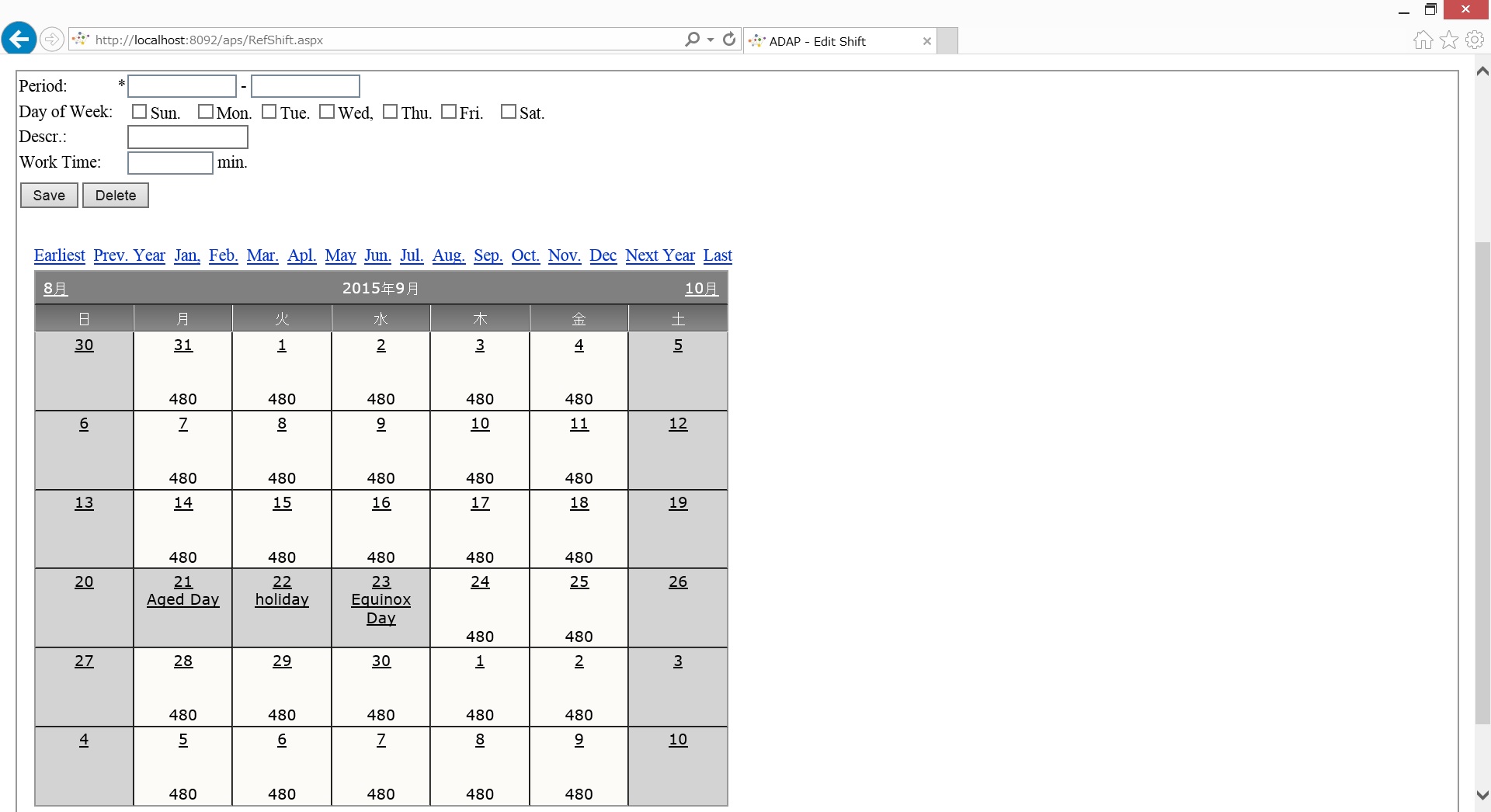

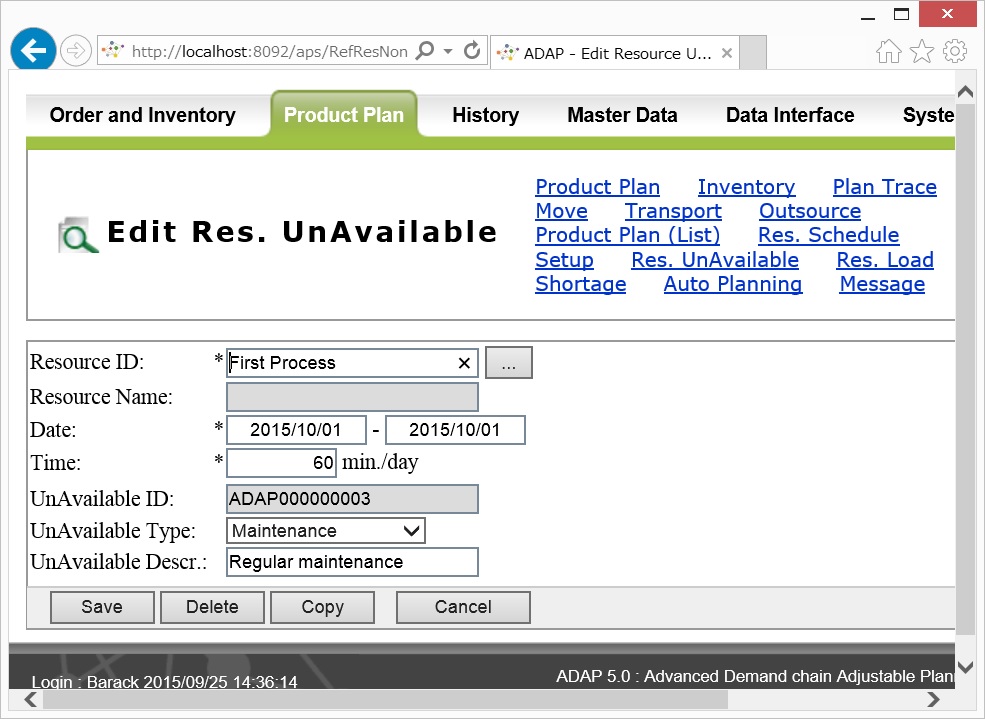

Flexible Adjustment Capability, High-end Scheduling and High-end Work Calendar Synchronized with Scheduling

ADAP can handle not only work-shifts and exceptional rules, but also maintenance, prototyping, curing, and quality inspections in detail. The specified items are automatically reflected to load calculations and lead-time estimation.

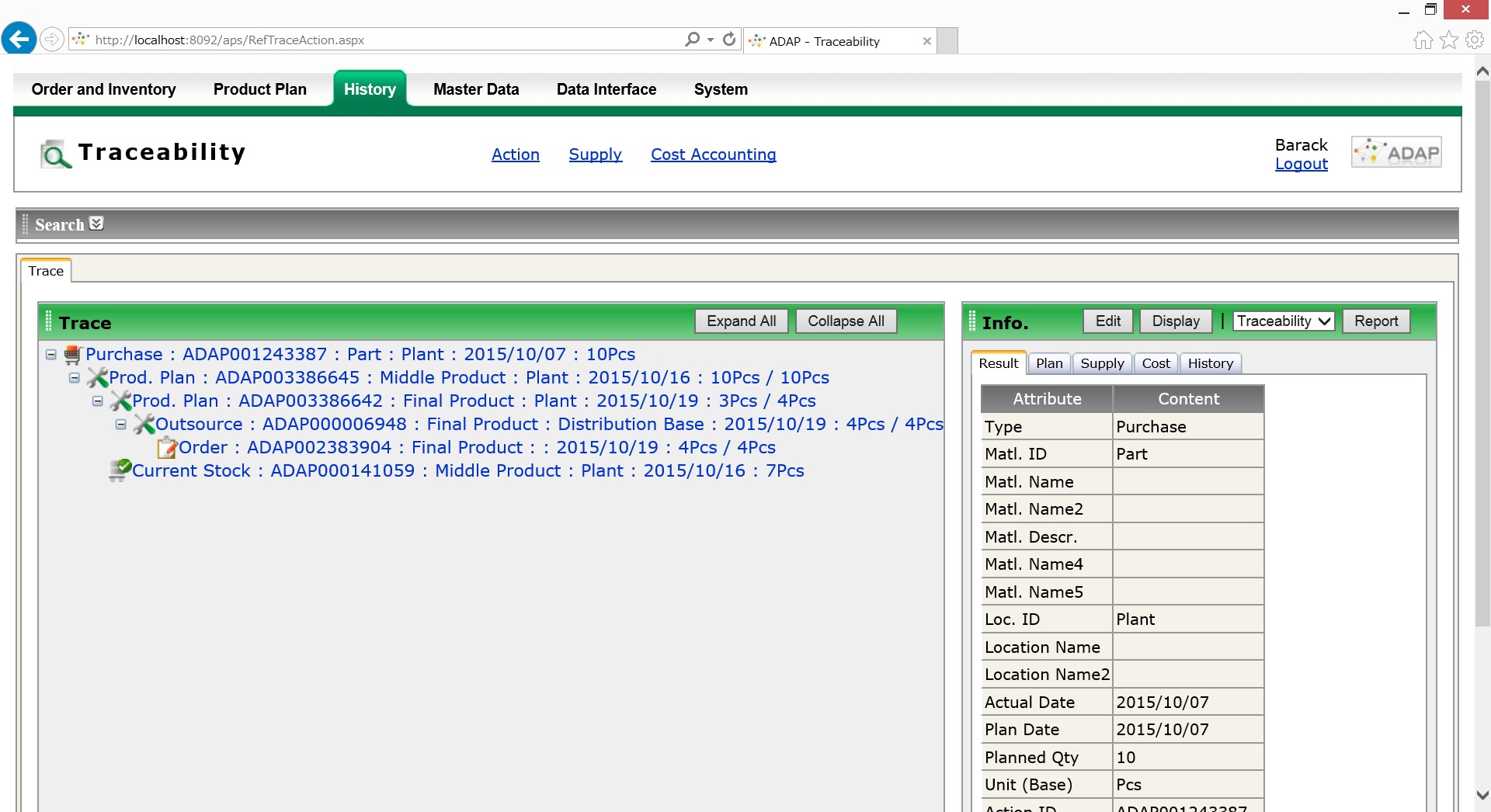

High traceability enabled by production result management by lot

Enhanced from the production result input function of the previous version, the latest ADAP can store production results by lot over several years.

This Traceability Function enables you to trace the defective lot and investigate the cause of malfunction (of product or equipment) at the time of defect products, as well as detecting the products of call-back.