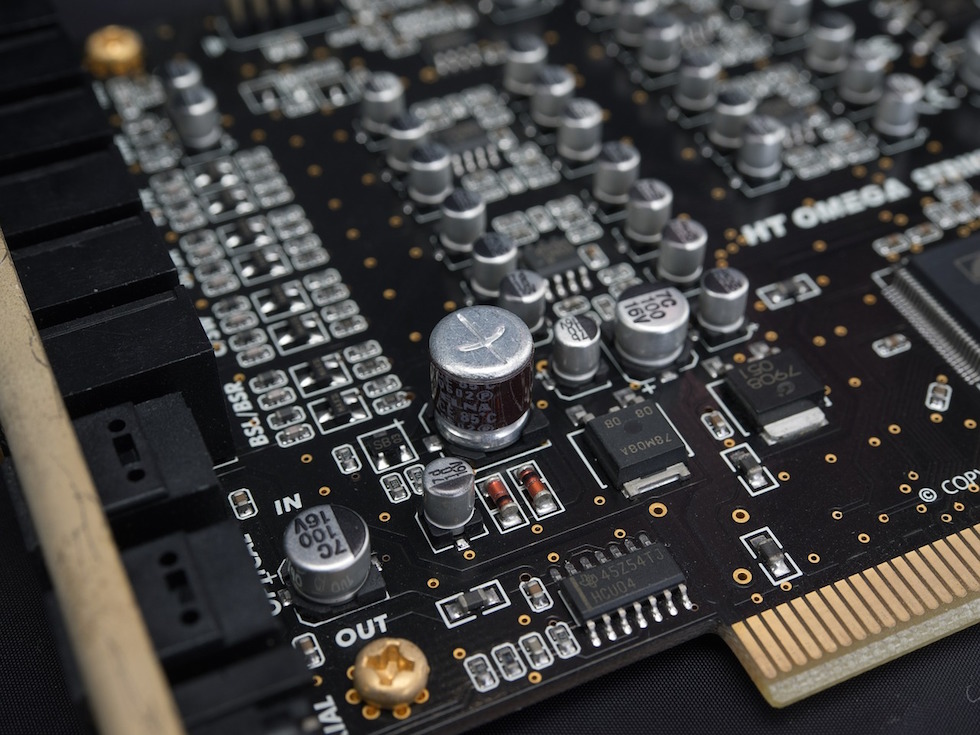

Communication Device Manufacturer

Intermediate stock down to 1/5. No more picking mistakes.

Customer's Issues

The workflow of mounting and inspection got switched somehow, and substrate was not finished the way it should be. The final assembly got delayed because of the additional time required to obtain the proper substrates, which caused overdue delivery. The space for storing intermediate products for substrates were crowded with various intermediate products, and caused many picking mistakes.

Point of Improvement

By adjusting the supply schedules and the order of work processes to add up at the last assembly, waiting time for substrates was considerably reduced. The production lot size, however, was not changed, and the productivity did not decline.

Benefits

The manufacturing lead-time used to be 15.5 days from launch to completion, which was shortened to 6 days. As a result, the ratio of meeting delivery date was improved from 84% to 94%. Now the space we need for intermediate substrates is trimmed to one fifth compared to before, which enhanced the work efficiency of picking process with no more picking mistakes.